The degree of automation in order fulfillment processes can vary based on factors such as the nature of the product, speed requirements, and investment considerations. To achieve the desired level of automation, a wide range of conveyor and sortation technologies can be combined and tailored to engineer effective order fulfillment solutions. Consequently, conveyor systems play a crucial role in enhancing productivity and ensuring the safe handling of delicate packages within the manufacturing facilities of industries like Food and Beverages, Consumable goods, Breweries, FMCG, Parcel and Distribution Warehouses, Pharmaceuticals, and more.

However, the use of outdated conveyor technology poses several challenges, including increased maintenance efforts, higher energy consumption, and elevated costs associated with maintaining multiple moving parts in traditional conveyor systems.

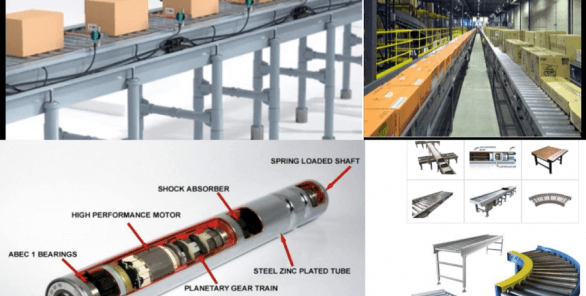

To address these issues, the Motorized Drive Roller (MDR) conveyor system has emerged as a revolutionary technology, gaining popularity among users and manufacturers due to its numerous benefits. The MDR system utilizes self-contained motorized drive units, enclosed within individual rollers, to power specific segments or zones of the conveyor. This is achieved through a 24V dc brushless motor within each roller, driving the conveyor effectively.

DE ALLIANZ GMBH offers comprehensive services, including design specifications, procurement, installation, and commissioning, to deliver MDR conveyor system solutions with non-contact zero pressure cumulation and product protection for their esteemed customers. Collaborating with major OEMs like Hilmot and Pepperl+Fuchs, they combine cutting-edge material handling equipment technology and industrial sensors to surpass their clients' organizational goals.

Regardless of the industry, whether manufacturing machinery on an assembly line, packaging pharmaceuticals or food-grade goods, or simply conveying bins, totes, and cartons within facilities, DE ALLIANZ GMBH provides MDR conveyor solutions tailored to specific weight capacities and widths. Optional control cards offer remarkable versatility for various accumulation activities, including slug and cascade release. The load capacity of the MDR system can be customized to accommodate anything from light-duty items to heavy loads, ranging from a few pounds to several thousand pounds per motorized zone.